When you enjoy an ice cold beer on tap at your favorite local restaurant, you’re probably not thinking about the complex refrigeration process happening just below the surface of the bar. But restaurant and brewery owners know just how critical specialized equipment is to delivering that perfectly chilled golden ale to your table.

One of the key components of the advanced system of beer cooling and serving technology is a glycol chiller, which works overtime to maintain the cool temperature of your beer as it travels—sometimes long distances—from storage to tap.

Whether you’re a beer enthusiast or a restaurateur in search of your next bar upgrade, read on to learn how this one piece of equipment can turn your on-tap lukewarm letdown into a refreshingly crisp brew.

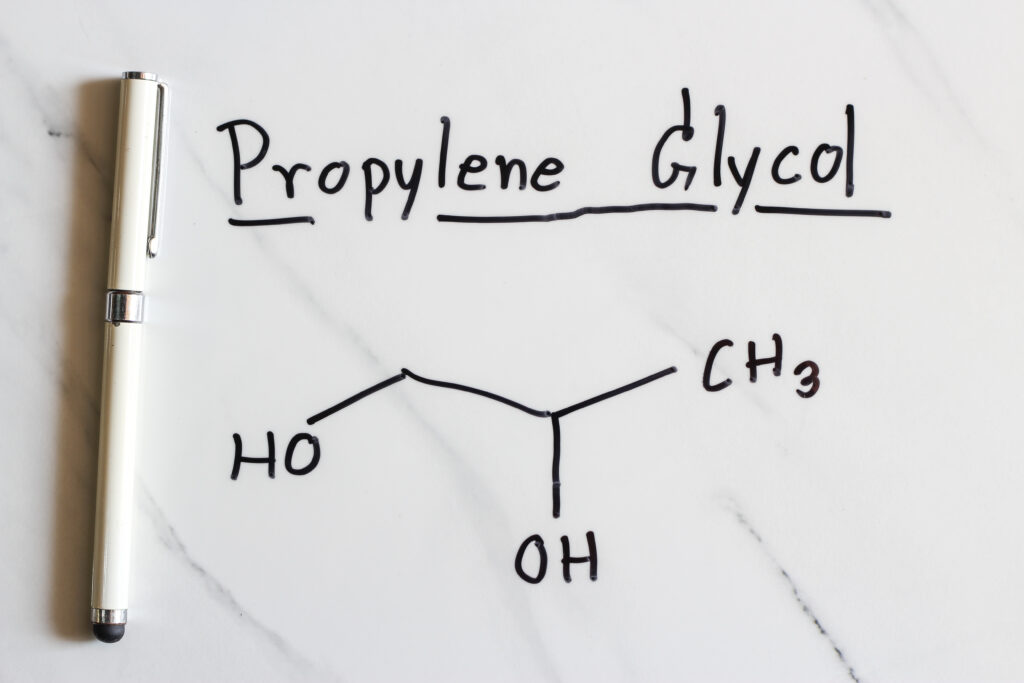

Propylene glycol is the star of the glycol chiller show

A glycol chiller is a special type of refrigeration unit designed to cool liquids using propylene glycol as an energy efficient way to transfer heat.

Propylene glycol is a colorless, odorless, and slightly thick and viscous liquid you can find in a variety of industrial, commercial, and household applications. It can be used as an anti-caking agent, a preservative, or a thickener in foods, or as a moisturizing humectant in cosmetics. Some pharmaceutical companies even use propylene glycol to stabilize the medication in capsules and tablets.

What makes this special substance particularly helpful in brewery refrigeration systems and brewery chillers is its fantastic ability to absorb heat quickly, while using very little energy. Plus, food-grade propylene glycol is approved for human consumption, so it can be handled easily and safely in your kitchen or brewery.

As the beer passes through a network of propylene glycol-powered tubes, it’s instantly chilled—and refreshingly cool.

In a typical draft beer system, the glycol chiller is used to maintain the temperature of the beer as it travels to your bar’s beer tap. Without this system in place, the beer trapped in the tubes between beer pours would warm and sour—leading to a less-than-pleasant tasting experience.

Just beneath the bar, you’ll find a compressor, condenser, evaporator, and a glycol tank. The propylene glycol stored in it is circulated through a closed loop system that runs from the glycol chiller to the beer lines, then back to the chiller.

As the propylene glycol circulates, it absorbs extra heat from the beer lines, dissipates that heat through the condenser, then returns to the storage tank for reuse.

For long-draw beer systems, a glycol chiller is a must-have.

The biggest benefit of installing a glycol chiller in your restaurant or brewery refrigeration system is that it allows your beer to be dispensed over long distances without compromising quality along the way. With a long-draw system in place, often used in large bars, restaurants, and breweries, you can store your beer away from the action without risking your brew warming as it’s dispensed.

If you’re skeptical of the value of a glycol chiller, consider this: Rising temperatures don’t just change the flavor of beer, they impact its carbonation, foam, and aroma. In the past, to maintain that perfect temperature, owners had to keep their beer kegs and entire restaurant or brewery refrigeration system within a few feet of the taps—taking up limited bar space or crowding the kitchen. But with this glycol chiller technology, you can have an even larger and more complex draft beer system without impacting the beer’s quality along the way.

Looking for a commercial HVAC and refrigeration partner for your restaurant or brewery?

At Refrigeration Heroes, we’re the easy first call for local businesses across North and South Carolina. Our HVAC and refrigeration system professionals install, maintain, and service your critical systems—so you can worry less and serve more customers. To schedule service or sign up for our preventative maintenance plan, call (864) 834-4078 in South Carolina or (828) 688-0323 in Western North Carolina.